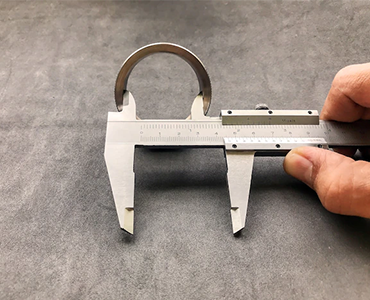

Micson Corporation's certified quality management begins with the inspection of the material to be processed and continues throughout the entire production process up to dispatch. All results of the dimensional inspection as well as all attributive characteristics are determined and documented in accordance with the inspection planning and the subsequent test data acquisition.

Micson Corporation is an ISO 9001:2015 certified company. These are international standard that specifies equirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements, 5’S Systems ERP.

Our product tools are designed to comply with both US and European standards and specifications.

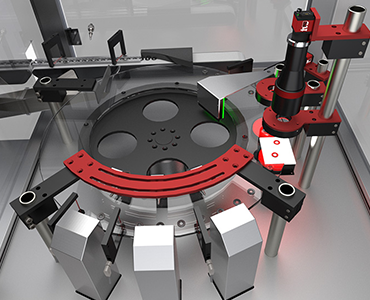

Micson Corporation has designed its QMS by keeping online Quality Check Points at each strategic process. All the Measuring equipment is calibrated from time to time to ensure strict quality control.

Micson Corporation has designed its QMS by keeping online Quality Check Points at each strategic process. All the Measuring equipment is calibrated from time to time to ensure strict quality control.

Machines are the heartbeats of the production process, keeping it smooth and functional is a must for delivering quality components. Micson Corporation conducts regular machine maintenance to keep up the quality standards

Micson Corporation has developed unique practical and theory training programs for different departments. Human Assets go through this training for 28+ hours a year to achieve excellence in their department.

Micson Corporation has developed unique practical and theory training programs for different departments. Human Assets go through this training for 28+ hours a year to achieve excellence in their department.

Micson Corporation has a professional internal laboratory to ensure the stability of product quality and advancement. After years of continuous investment in internal experiments, a standardized and professional metal product testing system has been formed. It covers material composition testing, material hardness testing, surface salty spray testing, coating thickness testing, torque testing, etc. Here is the list of instruments we use for Quality control